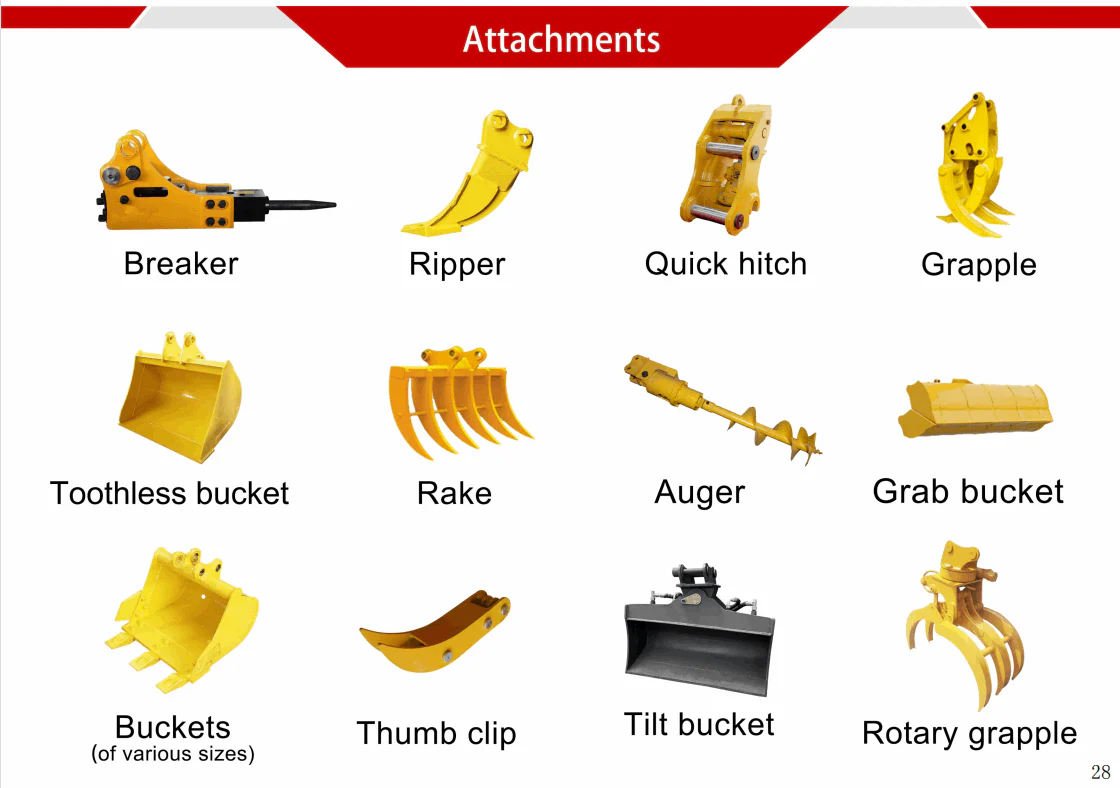

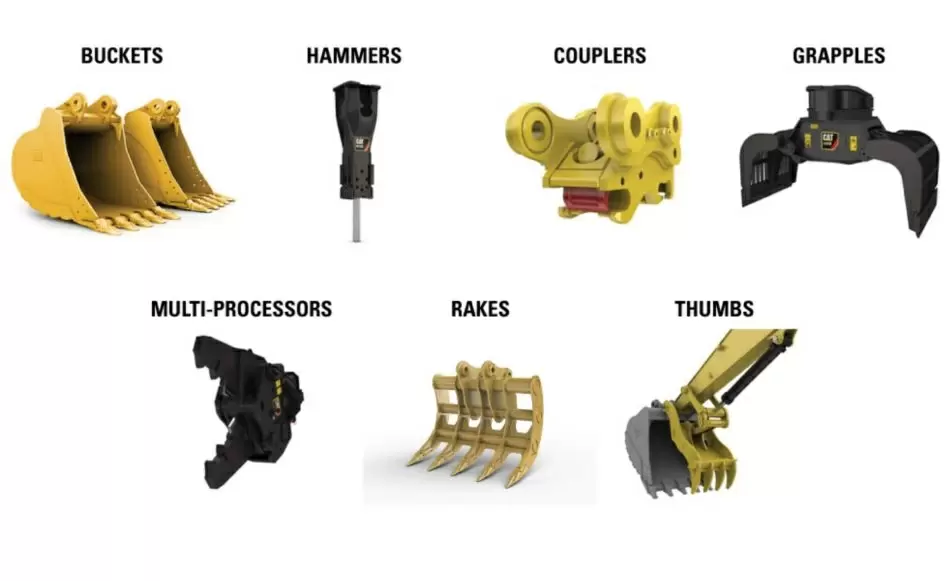

Excavator attachments, such as buckets, hammers, augers, and grapples, are tools that can be swapped onto the arm of an excavator to perform specific tasks like digging, breaking, drilling, or handling materials, enhancing the machine’s versatility and efficiency.

Choosing the Right Excavator Attachment: A Comprehensive Overview for Construction Professionals

Excavators are versatile machines that are used in a wide range of construction and excavation projects. One of the key factors that make excavators so versatile is the wide variety of attachments that can be used with them.

These attachments can greatly expand the capabilities of an excavator, allowing it to perform a wide range of tasks, from digging and trenching to lifting and demolishing. Some of the most common types of excavator attachments include buckets, thumbs, rippers, hammers, and augers.

Buckets are perhaps the most commonly used excavator attachment, and they come in a variety of sizes and shapes to suit different tasks. There are general purpose buckets for digging and moving soil, rock buckets for handling larger rocks and debris, and trenching buckets for digging narrow trenches.

Thumbs are another common attachment, and they are used to grip and lift objects such as rocks, logs, and debris.

Rippers are used for breaking up hard ground, while hammers are used for breaking up concrete and other hard materials. Augers are used for drilling holes, and they are commonly used in tasks such as installing fence posts and planting trees.

Here’s a table to help choose the right excavator attachment based on the task:

| Task | Recommended Attachment | Description |

|---|---|---|

| General Digging | Standard Bucket | Ideal for digging and moving soil, gravel, and sand. |

| Trenching | Trenching Bucket | Narrower than standard buckets, perfect for digging trenches. |

| Breaking Concrete/Rocks | Hydraulic Breaker (Hammer) | Powerful attachment for breaking up concrete, asphalt, and rocks. |

| Earth Drilling | Auger | Drills holes for posts, poles, and tree planting. |

| Material Handling | Grapple | Versatile tool for picking up and moving logs, debris, and other materials. |

| Demolition | Pulverizer | Crushes and pulverizes concrete structures. |

| Landscaping | Tilt Bucket | Allows for angled digging and precise grading. |

| Stump Removal | Stump Grinder | Grinds down tree stumps and roots. |

| Compacting Soil | Compaction Wheel/Plate | Compacts soil for foundations and trench backfills. |

| Clearing Land | Brush Cutter/Mower | Cuts through thick brush, grass, and small trees. |

| Grading and Leveling | Grading Blade | Smooths and levels surfaces for final grading. |

| Pipe and Utility Work | Pipe Grapple | Specialized for handling pipes and cylindrical materials. |

| Dredging/Underwater Work | Dredging Bucket | Designed for dredging and underwater excavation tasks. |

Factors to Consider When Choosing an Excavator Attachment

When choosing an excavator attachment, there are several factors that need to be taken into consideration. One of the most important factors is the type of task that the attachment will be used for. Different attachments are designed for different tasks, so it’s important to choose an attachment that is well-suited to the specific job at hand. For example, if the task involves digging trenches, a trenching bucket would be the most appropriate attachment to use. On the other hand, if the task involves breaking up concrete, a hammer attachment would be the best choice.

Another important factor to consider is the size and power of the excavator. Excavator attachments are designed to be used with specific sizes and types of excavators, so it’s important to choose an attachment that is compatible with the excavator that will be used. Using an attachment that is too large or too small for the excavator can result in inefficient operation and potential safety hazards. Additionally, the hydraulic flow and pressure of the excavator also need to be taken into consideration when choosing an attachment, as different attachments require different hydraulic capabilities to operate effectively.

Popular Excavator Attachments for Various Construction Projects

Excavators are used in a wide range of construction projects, and there are many different types of attachments that are commonly used in these projects. One of the most popular attachments for general excavation and earthmoving tasks is the standard digging bucket. These buckets come in a variety of sizes and shapes to suit different tasks, and they are used for digging and moving soil, rocks, and other materials. Another popular attachment is the hydraulic hammer, which is used for breaking up concrete, rock, and other hard materials. Hydraulic thumbs are commonly used for gripping and lifting objects, while rippers are used for breaking up hard ground.

In addition to these common attachments, there are also specialized attachments that are used for specific tasks. For example, augers are commonly used for drilling holes for fence posts, trees, and other purposes. Tiltrotators are another specialized attachment that allows the excavator to rotate and tilt the attachment, providing greater flexibility and precision in tasks such as landscaping and road construction. Other specialized attachments include grapples for handling logs and debris, and compactors for compacting soil and other materials.

Assessing Your Project Needs and Requirements

When choosing an excavator attachment for a construction project, it’s important to carefully assess the specific needs and requirements of the project. This involves considering the type of tasks that need to be performed, the materials that need to be handled, and the overall scope of the project. For example, if the project involves digging trenches for laying pipes, a trenching bucket would be the most appropriate attachment to use. On the other hand, if the project involves demolishing a building, a hydraulic hammer attachment would be needed.

It’s also important to consider the environmental conditions of the project site, as well as any potential obstacles or hazards that may be present. For example, if the project site is located in a densely populated area, noise and vibration from certain attachments, such as hydraulic hammers, may need to be taken into consideration. Additionally, if the project site has limited space or access, compact or specialized attachments may be needed to ensure that the excavator can perform the necessary tasks effectively.

Matching the Excavator Attachment to the Excavator Size and Power

Matching the excavator attachment to the size and power of the excavator is crucial for ensuring safe and efficient operation. Excavator attachments are designed to be used with specific sizes and types of excavators, and using an attachment that is too large or too small for the excavator can result in inefficient operation and potential safety hazards. Additionally, the hydraulic flow and pressure of the excavator also need to be taken into consideration when choosing an attachment, as different attachments require different hydraulic capabilities to operate effectively.

When choosing an excavator attachment, it’s important to consult the manufacturer’s specifications and guidelines to ensure that the attachment is compatible with the excavator. This includes considering the weight and lifting capacity of the excavator, as well as the hydraulic flow and pressure ratings. It’s also important to consider the reach and working range of the excavator, as well as any potential limitations or restrictions that may affect the use of certain attachments.

Evaluating the Quality and Durability of Excavator Attachments

The quality and durability of excavator attachments are important factors to consider when choosing an attachment for a construction project. High-quality attachments are designed to withstand the rigors of heavy-duty construction and excavation tasks, and they are built to last for many years of reliable use. On the other hand, low-quality attachments may be prone to premature wear and failure, which can result in costly downtime and repairs.

When evaluating the quality and durability of an excavator attachment, it’s important to consider factors such as the materials used in the construction of the attachment, as well as the design and engineering of the attachment. High-quality attachments are typically made from high-strength steel and other durable materials, and they are designed to withstand the forces and stresses that are encountered in construction and excavation tasks. Additionally, high-quality attachments are often backed by comprehensive warranties and support from the manufacturer, providing added peace of mind for the user.

Exploring the Benefits of Hydraulic Excavator Attachments

Hydraulic excavator attachments offer a wide range of benefits for construction and excavation projects. One of the key benefits of hydraulic attachments is their versatility and flexibility, as they can be easily and quickly swapped out to suit different tasks. This allows the excavator to perform a wide range of tasks, from digging and trenching to lifting and demolishing, without the need for multiple machines or attachments. Additionally, hydraulic attachments are often more powerful and efficient than other types of attachments, allowing for faster and more productive operation.

Another benefit of hydraulic excavator attachments is their precision and control. Hydraulic systems allow for precise and smooth operation of attachments, providing greater accuracy and efficiency in tasks such as grading, landscaping, and road construction. Additionally, hydraulic attachments can be easily adjusted and fine-tuned to suit the specific requirements of the task at hand, providing greater flexibility and precision in operation.

Budgeting for Excavator Attachments and Maintenance Costs

When budgeting for excavator attachments, it’s important to consider not only the initial purchase cost of the attachment, but also the long-term maintenance and operating costs. High-quality excavator attachments may have a higher initial purchase cost, but they are often more durable and reliable, resulting in lower long-term maintenance and repair costs. On the other hand, low-quality attachments may have a lower initial purchase cost, but they may be prone to premature wear and failure, resulting in higher long-term maintenance and repair costs.

In addition to the purchase cost and long-term maintenance costs, it’s also important to consider the potential return on investment of the attachment. High-quality attachments that are well-suited to the specific needs of the project can result in greater productivity and efficiency, which can ultimately lead to cost savings and increased profitability. Additionally, high-quality attachments may have a higher resale value, providing added value for the user when the attachment is no longer needed.

Safety Considerations When Using Excavator Attachments

Safety is a top priority when using excavator attachments, as these attachments can pose potential hazards to the operator and other workers on the job site. It’s important to carefully follow all safety guidelines and recommendations provided by the manufacturer of the attachment, as well as any relevant safety regulations and standards. This includes ensuring that the attachment is properly installed and secured to the excavator, as well as conducting regular inspections and maintenance to ensure that the attachment is in safe and proper working condition.

In addition to proper installation and maintenance, it’s also important to consider the potential hazards and risks associated with the specific tasks that will be performed with the attachment. For example, tasks such as lifting and demolishing can pose unique safety challenges, and it’s important to take appropriate precautions to mitigate these risks. This may include using additional safety equipment such as harnesses and fall protection, as well as implementing safe work practices and procedures.

Tips for Properly Maintaining and Caring for Excavator Attachments

Proper maintenance and care are essential for ensuring the long-term reliability and performance of excavator attachments. Regular inspections and maintenance can help to identify potential issues and prevent premature wear and failure, resulting in lower long-term maintenance and repair costs. It’s important to follow the manufacturer’s recommendations and guidelines for maintenance, including regular lubrication, cleaning, and inspection of the attachment.

In addition to regular maintenance, it’s also important to properly store and transport excavator attachments to prevent damage and premature wear. This may include using protective covers and storage racks to prevent exposure to the elements, as well as using proper lifting and handling equipment to prevent damage during transportation.

Additionally, it’s important to properly train and educate operators and maintenance personnel on the proper use and care of the attachment, as well as any potential hazards and risks associated with the attachment. By following these tips and recommendations, users can ensure that their excavator attachments remain in safe and proper working condition for many years of reliable use.

Leave a Reply